The Complete Guide To Retail Packaging

We see this a lot: simple, non-custom Retail Packaging that gets the job done. How can you expect to hit your sales target if you don't invest in your presentation at the store?

You have a great product, but you left out one thing - your Packaging! Retail Packaging is a great way to grab your customer's attention at retail and even online.

The best packaging even creates brand loyalty - 52% of customers return for business if they like the packaging. It's an easy thing for most brands to overlook, but this is exactly the issue we aim to solve. Working with a Packaging Manufacturer can be a huge benefit for you and your brand.

Creating an unboxing experience is the biggest challenge facing brands. Personalization needs to be a priority!

We help upgrade brands from plain to premium, and take advantage of all the latest technical and marketing innovations to create new designs and, more importantly, increase your sales.

Bringing new packaging ideas to life can be a challenging task. That’s why we created this guide to walk you through each step.

Talk with our team today about your next Retail Packaging

How Retail Packaging helps your product

- Protect your products during shipping

- Tell your brand story and connect with your customer

- Include product benefits and valuable information

- Stand out to a consumer to increase their consideration

- Encourage customers to take a closer look

- Explain how to use your product

Table Of Contents

Step 1: Determine Your Retail Packaging Needs

- What type of Retail Packaging do I need?

- Are there new innovations I can implement?

- What type of product is it?

- What dimensions do I need?

- How many units do I need?

- How can this be an extension of my brand?

A) What type of Retail Packaging do you need?

The type of packaging you need will vary depending on your product. This will be based on the size, shape, and weight.

If you have a fragile product, consider a solution that is structurally safe and includes adequate cushioning.

B) Are there new innovations you can implement?

Getting ahead of your competition is important. You should research or find a trusted packaging partner who can provide you with accurate and up-to-date information on the latest innovations in the marketplace.

There are numerous new and exciting ways to reach customers, and if you're creating a new packaging design, you should incorporate some of them.

Related: 7 Design Tips For Walmart Packaging.

C) What type of product is it?

Each industry has its own trends, and while you don’t want to fit in, you want to make sure that your customer can immediately identify you as a member of that industry.

So, either conduct some research on your competition or reach out to a trusted packaging company for some pointers.

D) What are your packaging dimensions?

Start by measuring the height, width, and length of your product, as well as the dimensions of everything you plan to put inside the box.

Then, consider the type and size of any protective packaging inserts you plan to use. This will determine the size of the box you need.

Pro Tip: Minimize your box as much as possible. This will allow the product to fit safely and avoid any shipping damage. Most importantly, you will reduce your costs and carbon footprint.

E) How many units do you need?

How much do you plan to sell? Do you need 100 units? 500? 1,000? 10,000? Will you need recurring orders?

This will directly affect your costs, and the more you order, the better the deal you can get.

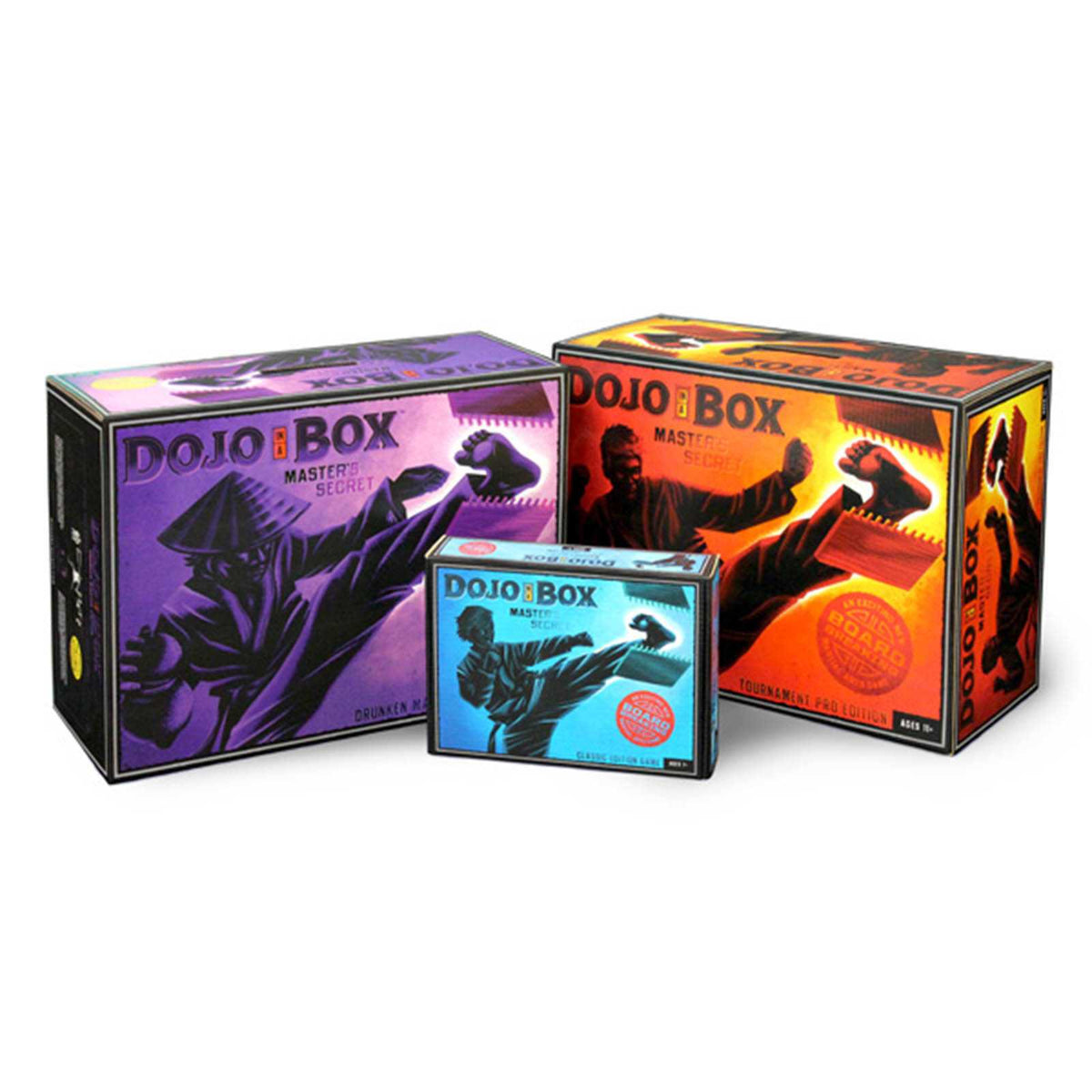

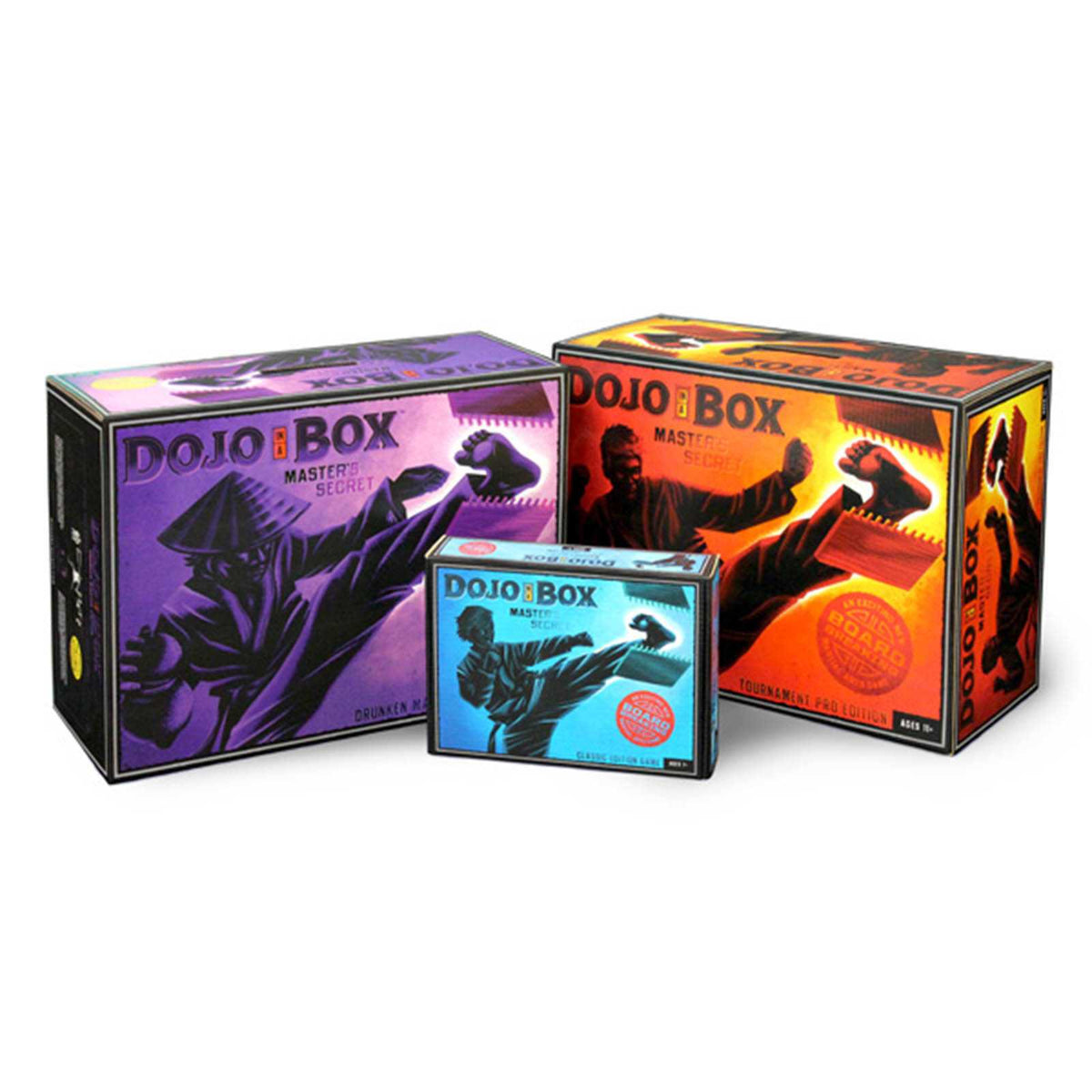

F) How can this be an extension of your brand?

This is a critical part of Step 1. You want to create packaging that not only fits the product, but also aligns with your overall branding and marketing strategy.

From the color choices, fonts, information, and images you include, these all tell the customer exactly “who you are” and shouldn’t be chosen lightly.

Step 2: Establish Your Packaging Budget

There are two types of costs associated with new packaging.

- Visible costs: such as the upfront cost of design and the price of the packaging itself.

- Hidden costs: such as additional filler, breakage, and more.

Your budget should include the cost of Packaging Supplies and Shipping Boxes. If any kind of packaging fillers are required, you need to account for them. You can also include a Contract Packager to help with fulfilment or assembly.

By using a company like Bennett, you get Turnkey Solutions that help you minimize costs.

A successful Retail Packaging program needs a budget that considers the economics of the entire process. You should consider the price of your product, your profit margin, anticipated sales, and the length of time you expect your Packaging to be in place.

Setting a budget or at least a range for your Packaging helps the process not become inefficient or aimless.

Related: How To Find A Corrugated Box Manufacturer

Volume purchasing

As with most printed products, you only really get a good value at high purchase quantities, due to the economics of scale. If you don’t buy in bulk, each package will add an unreasonable amount of expense to each shipment.

If you do buy in bulk, you will not only be putting more money up front for production, but also for storage, transportation between warehouses and handling.

Digital allows you to have complete flexibility for this.

The higher the sales price of your product, the more you should consider investing in your retail packaging.

Step 3: Designing The Outside

What elements of your brand need to be seen immediately?

In brick and mortar stores, customers won’t open the box - so you need to tell them what’s inside. It’s best to assume that they know nothing about your product or brand.

Did you know that 75% of consumers are influenced by package design?

Elements to include for brick and mortar stores:

- Your logo and tagline

- Social Proof/quotes from satisfied customers

- An image of your product

- Information Architecture/company story

For Retail Packaging that will become e-commerce, you know your customers will open the box. So priorities of what to include are different, but still similar. It’s best to use this situation for more brand awareness.

Elements to include for e-Commerce:

- A logo that stands out on the package

- Information Architecture/company story

Pro Tip: If you’re not a designer and don’t have a design team, we provide access to our award-winning in-house team in Creative Services.

Step 4: Designing The Inside

The inside of your packaging is less important when in a physical store compared to e-commerce. Still, it’s always a great idea to include product instructions or other materials for the consumer inside.

For e-Commerce, on the other hand, this is your opportunity to make a huge impression on your customer. Use the inside to tell your brand story, make your customer smile, or create something that encourages them to share the packaging on social media.

More customers post photos of products and packaging when the design is appealing.

What can you include to make their experience shareable?

Over 90,000 people search for unboxing videos every month! Your audience is looking at what that experience is.

These videos build a community around your brand online. When customers watch someone else open your package, they want to get their hands on that product! All of these unboxing videos should make it clear that you need to create better packaging.

Customers today expect a branded experience from start to finish. The marketplace has responded; so should you.

Related: 7 Design Tips For Costco Packaging.

Step 5: Choose a Printing Style

Choosing a printing option involves more than just considering cost factors. The technology has evolved over the years, and while some older methods remain proven and effective, newer methods have introduced entirely new ways to approach the marketplace.

Here are three printing options to consider:

Lithography Printing

When it comes to commercial printing needs, lithographic printing is the most used solution. And it’s great if you are creating a single design to print over and over without much customization.

One of the main issues is the upfront cost of the printing plate and the lead time for the project.

If you choose Litho, that means you’re committing to waiting and a portion of your budget before you even get your first box.

If you are looking for a high-volume production run of a single design, this is the way to go.

High Speed Digital Printing

Bennett's digital presses are game-changing for the custom retail packaging industry.

While other companies might tell you that Digital Printing isn’t competitive when running large orders, what they aren’t telling you is that with Digital Printing, you can run a variety of designs without needing to pay for, or wait for, new printing plates to be made.

Digital has been growing in the industry, but only a few brands have actually started to take advantage of this huge opportunity.

Imagine creating regional messaging and designs for different stores, as well as seasonal or product variation sizes, all without incurring additional costs.

We were the first to invest in a high-speed, single-pass, direct-to-corrugate, 6-color digital press of its kind in North America. If you want to learn more, check out our page on Digital.

Flexography Printing

Flexographic printing can reduce your printing costs, and tooling costs are typically lower. It has a fast turnaround time that can use both water and oil-based inks.

However, compared to Lithography and Digital Printing, Flexography has noticeably lower printing quality.

It cannot create photo-quality images, and smooth colors or gradients will have visible banding.

The colors aren’t as vibrant or crisp as those of the other two options, but this printing format is inexpensive. It also doesn’t require a lot of attention to detail, and can be produced at a very high speed.

Related: Printing Coating Options

Designing With Digital

Here are some design tips to create an effective Retail Packaging from the ground up:

Information Architecture

Messaging needs to be clear and motivated. What should your customer know as they pass by the Packaging? What can they see from across the store? Keep it concise and focused! Only the important benefits should be included here.

Retail Packaging Product Showcase

Retail Packaging is all about showcasing your product in an appealing way to attract customers. This can be a die-cut window to allow customers to touch the product, or a focus on high-resolution graphics on the outside.

Color Science

Each color speaks to the customer on a different emotional level; that's something all designers know. Why not use that on the store floor? Here's an actual opportunity to put that knowledge into practice and create something that matches your brand in a powerful way.

Match Your Brand Colors

Most manufacturers claim they can accurately match your brand colors, but they often lack the expertise to do so. We have some of the best printing capabilities in North America, and we promise to match with 100% accuracy.

Step 6: Do You Need Paper Coating?

A coating can be applied to complete your packaging’s look - while offering additional protection and even enhancement.

Matte Lamination

While the overall effect of matte laminated surfaces is understated and elegant, it creates a noticeably high-end and sophisticated feel to your packaging.

Gloss Lamination

This provides a beautiful shine, vibrancy, better image contrast, and more vibrant depth of color. Gloss lamination even provides better protection against things like moisture and dust.

AQ Coating

Is a clear, water-based coating that is capable of fast drying. It’s environmentally friendly, making it an excellent choice for food, household, and fast-moving products.

It has a very faint gloss finish compared to UV coating and lamination.

UV Coating

can create a similar look to lamination, but the difference is that UV is applied directly to the material. Packages are UV-coated using a flood or spot application.

Spot coating is applied to a specific area of the package, while flood (or overall) coating indicates a coating applied to the entire package. Spot UV is generally screen-coated in thick amounts for maximum visual "pop" and rub resistance.

While flood is usually roller coated in relatively smaller amounts.

Varnish

increases the perceived quality of the product. However, it offers a lower degree of protection in comparison to aqueous coating and UV coating.

They are also susceptible to yellowing over time. Varnishes are also not particularly eco-friendly. This is the least popular option.

There are other options, but these are the most popular.

Step 7: Do You Need Special Finishing?

Consider enhancing your packaging by adding a more impactful look & feel. You can include a variety of special processes to create a more eye-catching design.

Foil Stamping

Perception is everything. A product with a foil-stamped package can have a higher perceived quality and value, than one in a standard package.

Foil also draws attention, which can make your product stand out among a crowd of competitors.

Spot UV

Similar to UV coating, but this is applied to a specific area of the packaging, rather than coating the entire surface. This allows for these areas to be overprinted afterwards, as overprinting will not be successful on areas with UV varnish.

Embossing + Debossing

This will add dimension and depth to your packaging. Embossing and debossing a printed sheet create a raised (embossing) or lowered (debossing) area.

It is formed using male and female moulds or dies.

Window Cutting

Small windows can allow consumers to see the product inside and even let them touch and use it.

Toy packaging often uses windows to allow consumers to press a button or interact with the toy.

Step 8: Creating a Dieline

Now that you have your design in place, it’s time to transfer it to the structure template, also known as the dieline.

There are a few dieline and artwork preparation and requirements that need to be noted by your designated designer, even if your artwork is done and ready to go.

If you don't have a designer, your packaging company will take care of this for you.

Dielines

A dieline is typically created on a computer with a designing tool such as Adobe Illustrator, Artioscad, or Adobe InDesign. Measurements need to be precise, to save time and money.

Step 9: Preparing The Artwork

Working with your packaging partner, you will deliver high-resolution quality artwork for printing. It’s best to speak directly with the company you are working with to determine the exact specifications for their CMYK printing.

At Bennett, we offer access to our award-winning Creative Services to help you design, prep, and deliver all your artwork to our manufacturing teams - and ensure your project details are correct every step of the way.

Pro Tip: Need more clarification on preparing your artwork? Reach out to Bennett if you need help with any of your designs!

Step 10: Creating Prototype Retail Packaging

You should always request a prototype box to confirm the structure and printing for final production, especially if you have a very large order. Once the prototype is created, it can be delivered to you in person or via mail carrier.

We have an array of equipment in our Creative Services Department that matches the exact quality of our High-Speed Digital Printers, allowing you to quickly produce prototypes and move your project along to production.

Step 11: Production + Shipping

Once you finalize everything, your retail packaging is ready for full production. You can sit back, relax, and wait for the arrival of your packaging!

Receiving your shipment all depends on your requested timeline, the size of the package, the method of delivery, etc.

It varies depending on your situation, but your account manager will keep you informed about the production and shipping process, ensuring you stay on track.

Learn more about Contract Packaging

Pro Tip: If you need to order on a consistent basis, consult with a packaging specialist to determine your inventory needs and schedule. This will make it easier to maintain a healthy inventory flow and allow the manufacturer to know exactly when you need it.

Supply Chain Solutions

Once you have your Packaging design locked and production is ready, you need to create a Supply Chain plan. You should consider the entire process, from manufacturing and storage to retailer delivery, etc.

Key Questions:

- Will your Packaging be shipped fully assembled or KDF?

- What is the weight of your Packaging with your Shipping Box and Supplies?

- Where will you store your Packaging?

- What is the cost for Packaging Supplies?

- Fulfillment costs, if any?

- How will you account for returns?

Bennett Makes Custom Retail Packaging

Bennett is a premier packaging and retail displays manufacturing company striving to protect and promote our clients' products with customized corrugated solutions. When you work with us, you’re part of the family. We will partner with you every step of the way.

With our fully integrated design-to-delivery process, we can be the single-source supplier. We are an award-winning manufacturer of virtually anything corrugate. We offer everything from plain brown shipping boxes to sophisticated, high-graphic printed point-of-purchase displays, and everything in between.

Frequently Asked Questions

What is Retail Packaging?

Retail Packaging is a custom-designed package for a product. It incorporates your business’s logo, brand colors, copy, and message on the outside (and inside) of the box. This helps your brand stand out in-store and fosters customer loyalty.

Where can I order retail packaging boxes?

Bennett offers a wide variety of retail packaging boxes, including folding cartons, mailing boxes, and shipping boxes. No matter what kind of product you have or box you need, we can make it.

Do you also make Retail Displays?

Yes! We offer award-winning displays that can be designed in tandem with your packaging for your next campaign. By leveraging a single-source supplier, you can reduce costs and streamline the entire supply chain.

What’s the difference between “Solid Board” and “Corrugated Packaging”?

There are 2 main types of product packaging. Solid board (also referred to as carton board) is a solid material used to create boxes such as those used by Apple (for its iPhones/iPads, etc.). Corrugated packaging is made from cardboard. Both are suitable for retail applications.

What packaging is best for my product?

The style of box chosen for your product depends on a number of factors. This includes the size, shape, weight, and fragility of your product, as well as your target market. At Bennett, we offer a full spectrum of box styles that will elevate your brand from plain to premium.

What Printing Styles do you offer?

We are able to produce litho, Flexo, and specialize in digital. We were one of the first manufacturers to invest in Digital Printing, and that’s put us ahead of the curve. Typically, customers think Digital Printing is only useful for small runs, but Digital Printing allows you to create printing variations and produce multiple runs of different targeted designs - utilizing some of the latest innovations in marketing.