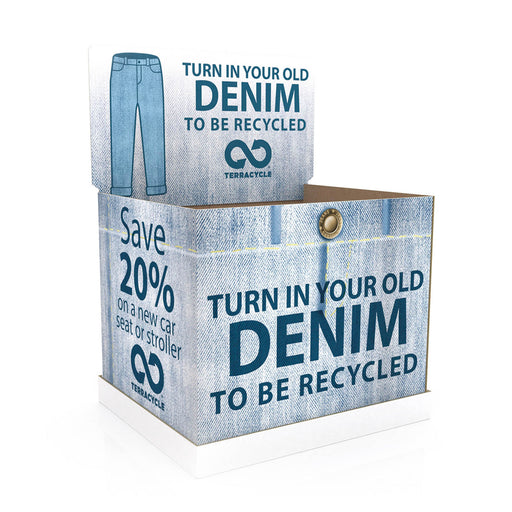

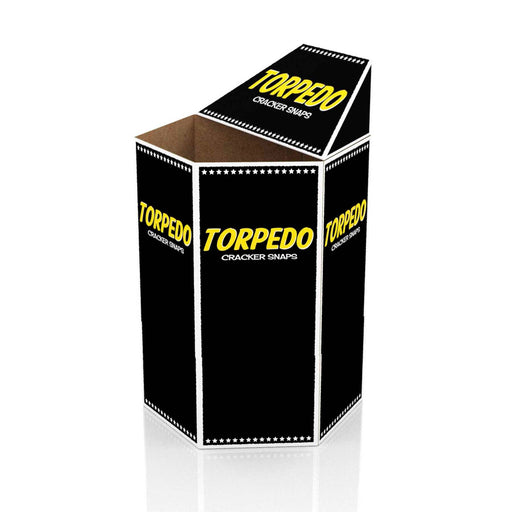

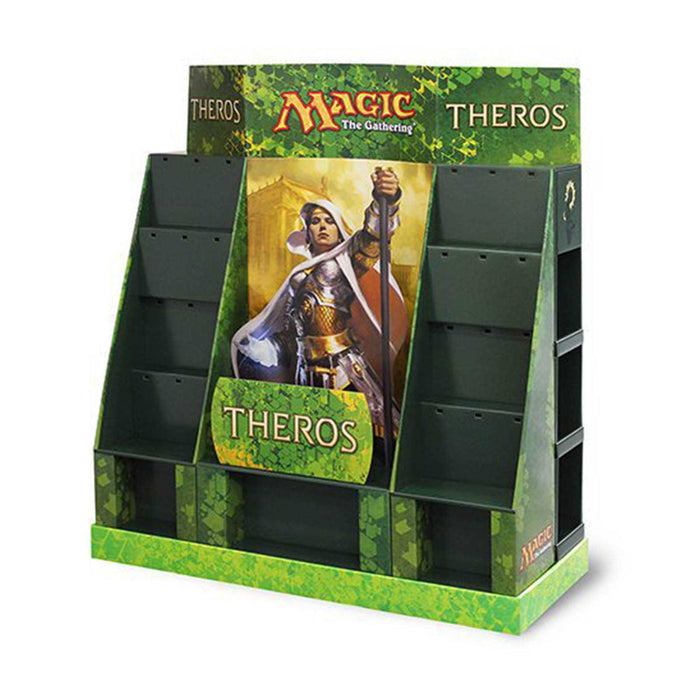

Want to grab your customers' attention in-store? Our custom Dump Bin displays are the answer. With designs that are sure to stand out from the competition, our Dump Bins create an unforgettable shopping experience. Plus, our team of structural designers will ensure that your display is both easy to shop and long-lasting, keeping your products front and center. Say goodbye to lackluster displays and hello to increased sales with our custom Dump Bins.

Top Tips for crafting the Perfect Retail Pallet Display

Table of Content Top tips for crafting the Perfect Retail Pallet Display Engaging Graphics and Branding The Power of Visual Appeal Strategic Product Placement Keep it Neat and Organized Durability and Safety Bennett Makes Pallet Displays The perfect Retail Pallet...