Spot color, also known as Pantone® Matching System (PMS), is a unique type of ink used for packaging printing. It is a specialized process that combines individual colors to create a wide variety of hues and tones. Unlike other methods like CMYK, spot color uses pre-mixed inks and customized color formulas to achieve the exact hue that a customer desires. The result is more vibrant, accurate colors when compared to other methods of printing.

But what does that all mean?

Table Of Contents

Spot Color Printing

What are Spot Colors?

Spot Colors is a customized formula of pre-mixed inks to create vibrant, accurate colors. This method uses individual colors that are combined together to achieve the desired hue and tone.

Using Spot Colors with Traditional Printing

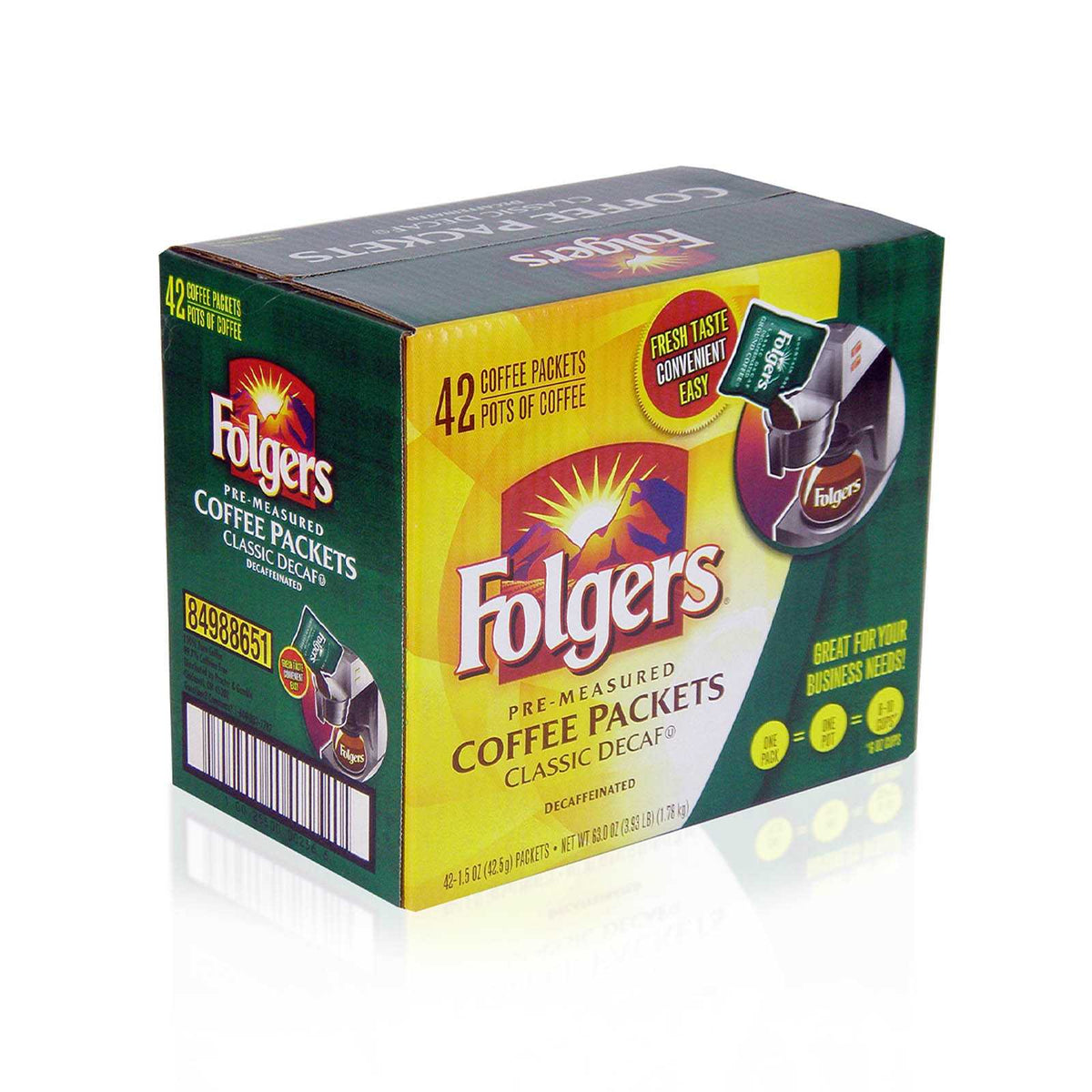

Spot Colors can create consistent results across different machines, print runs, and techniques. It's typically used in Flexographic printing, which offers up to 7-colors. The printing plates are pressed against the corrugated surface in layers to create a finished design.

Spot colors are created using a formula, which means the colors are consistent across print runs, machines, and print techniques.

While this method also has higher upfront costs, the cost per unit printed can be lower depending on the quantity ordering. Additionally, other setup is needed during production as spot colors are pre-mixed and ready to use.

Related: What Are Printing Plate And Cutting Dies?

When to Use Spot Color in Your Packaging Design

For a consistent and accurate brand presentation, spot colors are a great choice. Not only do they ensure visual consistency across multiple print jobs - but with specialty inks like fluorescents or metallics now achievable on some presses, your printed packaging will stand out.

Other print methods, like Digital, will produce wonderful results, but Spot Color is still the most accurate.

Can Digital Print Use Spot Colors?

With digital print for wide-format corrugated, Pantone spot colors are not an option - but don't worry! Digital presses can accurately match the vast selection of colors in the Pantone library. If your brand requires a specific shade, ask your packaging vendor to conduct swatch tests using one of the available Pantone options and select the matching CMYK version accordingly.

This will ensure that those vibrant shades remain consistent within all aspects of branding across materials used by you or via any third-party suppliers - making sure color accuracy is kept at its highest level.

Related: How To Use Color Theory In Packaging

Choosing Between Spot Color And Other Methods

Weighing the benefits of traditional analog printing versus digital printing for custom corrugated packaging can be daunting- after all, deciding on a method tailored to your needs and budget is key.

Choose Spot Color Because

- You require more than 7 colors.

- Color the most important part of the project.

- You are ordering a large amount of one design.

- You can afford the associated tooling costs.

- The lead time is long enough to allow for the tooling to be made.

Choose Digital Print Because

- Color is important, but you can adjust to the printing method.

- You are ordering a small amount or smaller amounts of multiple designs rather than one large order of a single design.

- You can't afford the tooling costs associated.

- The lead time is not long enough for tooling to be made.

- You want to reduce waste and your impact on the environment.

When it comes to package printing, color selection is more than just a matter of aesthetics. The production methods you choose for your project will directly impact how much it costs.

Flexography and litho-lamination require separate print plates for each spot color used on press - meaning that as the number of colors grows, so does the cost associated with them. It's an important factor to keep in mind when deciding which method best suits your budget.

CMYK Printing

What Does CMYK Mean?

CMYK is an incredibly powerful color model. The combination of Cyan, Magenta, Yellow, and Black inks open a whole world of possibilities. In flexography or litho-lam printing processes, these four colors are overlapped to create different hues, while digital print applies them simultaneously directly onto the surface. Together, they form virtually any shade imaginable - with only a small proportion not achievable through this system!

Using CMYK with Digital Print

CMYK inks are applied via inkjet directly to the material in individual tiny color dots for digitally printed packaging. At a distance, these dots blend so that they appear as one solid color.

Because packaging designers can render virtually any color using CMYK, digital print is the ideal method if your packaging involves full-color imagery or photography.

Minimum Order Quantity

Digital print is transforming the packaging industry, allowing brands to place orders for smaller quantities and adapt their designs with increased frequency - abolishing outdated analog printing methods. This opens up a realm of creative possibilities!

Eco-Friendly Production

Digital printing offers a powerful sustainability solution for businesses looking to reduce their environmental impact. By eliminating pre-press activities and enabling on-demand production of exact order quantities, digital print can help cut down on out-of-date packaging as well as waste associated with obsolescence - resulting in substantially lower ecological footprints without compromising quality or service.

High-quality CMYK printing is achievable - though subtle variations in color may occur between different printers or jobs. These variations are caused by a range of factors, including the software and technology used for production as well as resolution capabilities. It wouldn't be enough of a change to impact the look.

Which Color Model is Better?

When creating a memorable packaging design, your color choice is one of the most important decisions you'll make. Spot colors or CMYK? The answer lies within the purpose and production method for your prints - each offers unique advantages that can help deliver an eye-catching result!

Traditional Print vs Digital Print

Choosing between traditional analog printing and digital printing for custom corrugated packaging can be confusing.

Traditional Print

Traditional print is a more labor-intensive method that involves mixing inks manually to achieve the desired hue and tone. The pro is that the exact colors are typically closer to your brand colors, but the con is it has different costs and timelines.

A print like Flexography requires the use of printing plates to apply inks on the packaging, similar to a rubber stamp. Each individual color in a design will require a print plate, so multiple colors can be combined together to create a visually appealing outcome. Digital Printing, on the other hand, doesn't need printing plates.

Digital Print

High-Speed Digital Printing eliminates this step by utilizing pre-programmed colors so that accurate colors can be quickly applied directly onto the material. The advantage of digital print is that it requires less time for set-up and offers greater flexibility with regard to designs as well as faster turnaround times.

Related: Digital Print vs. Litho

Which Looks Better?

The precision of spot color remains largely unchanged regardless of the techniques used. However, it’s important to note that there may be slight variations when using either type of print process due to the differences between their respective capabilities and limitations.

In addition, each type of process has its own costs associated with production. Traditional Printing typically requires higher upfront costs but may offer lower costs per unit compared to Digital Print processes, which generally require less setup but cost slightly more per unit printed depending on the quantity ordered.

Regardless, both methods offer excellent quality results when creating custom corrugated packaging with spot colors when implemented correctly.

Order Custom Packaging From Bennett!

If you are looking for custom packaging solutions, Bennett Printing Services has got you covered with our high-quality printing capabilities. Contact us today to get a free quote, and let's bring your creative vision into reality!