Packaging Design Strategy

The first interaction your customer has with your product is your packaging. Whether that's seeing it or picking it up, holding it, and reading about your item.

Choosing the correct packaging will tell your customer the quality, importance, and what to expect from the product. That means it's as important to your packaging as your product.

With all the packaging and box options available on the market, it can be difficult for brands to choose the best one for their products. This blog will give you an overview of the options available and suggest which you should consider.

Table Of Contents

Packaging Questions

Here are some of the most important things to consider when designing packaging.

Package Materials

What materials will best protect your products? What fits in with your brand? What are the opportunities to reduce your carbon footprint? (Customers today are very concerned about this.)

Package Construction

Will you choose flexible or rigid support for your product? How fragile is your product? Which option reduces material costs? How much space do you need for brand messaging? Will it stand or hang at retail?

Secondary Packaging

Will the size and shape of my packaging design prevent a simple secondary packaging option to ship to retailers? This is an important step, and a proper packaging analysis can solve it.

Product Shelf Life

How long does your product last on the shelf before a purchase? Consider the expiration date, and your supply chain process.

Storage and Distribution

What is the cost of the secondary packaging and it’s transportation? How long will your product need to be stored before going on display? Will it be protected during this time?

Define Your Brand Identity

Packaging is sometimes the very first interaction your customers have with your products. It is your chance to define your brand identity and make a statement about who you are and who you are selling to.

Brand identity is all about clarity.

Key Questions

- What is my product?

- How is it different from similar products on the market?

- Who is my target customer?

- What is my company philosophy?

These answers will guide you during your design process to create something consistent with your brand identity goals.

This will help define your packaging materials, shape, color, and size.

8 Packaging Options For Your Products

1. Paperboard Box

Paperboard is a lightweight but solid paper-based material. It’s great at making custom shapes and structures and can be quickly cut and manipulated.

This makes it highly suitable for customized packaging. Fibrous materials such as wood or recycled waste paper are turned and then bleached into pulp. The pulp is available in different grades, each appropriate for various packaging requirements.

There are two main options: SBS (bleached) or Kraft / CUK (unbleached “brown” paperboard). Both are commonly used, but Kraft is more eco-friendly.

However, Kraft is less moisture resistant, which makes it less suitable for wrapping food-related items or frozen goods.

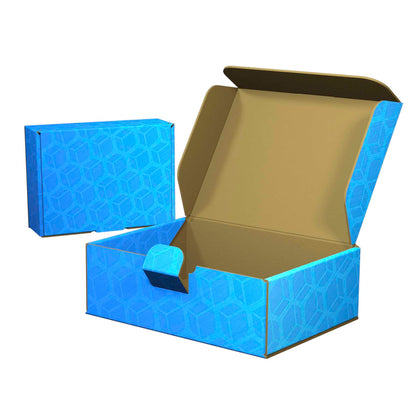

2. Corrugated Box

Corrugated actually refers to what is typically called cardboard. Cardboard boxes are most commonly known as large shipping, shoe, storage, and moving boxes.

It consists of three layers of paper. An outside liner, an inside liner, and a corrugated medium (called fluting). This corrugation gives the cardboard its strength and stiffness.

This packaging is mainly made of recycled raw materials, and the great news is that it can be recycled multiple times!

There are various kinds of corrugated boards: single-faced, double-faced, twin-wall, and triple-wall. These boards can be used to manufacture packaging with distinct features, performance, and power.

It has also become a common packaging option for e-commerce and product packaging. It’s cheap, lightweight, and cost-effective for protecting packaging in the mail.

3. Chipboard Packaging

This type of packaging is used in a variety of industries, typically in electronics, medical, food, cosmetics, and even some beverages.

Another type of paperboard is made from reclaimed paper stock. It can be cut, folded, and formed into almost any shape, making it an extremely cost-effective option.

Chipboard has various densities and strengths but is not useful for heavy items. This is typically for lightweight items like cereal, tissue boxes, and other household items.

Storage can also be an issue. Due to moisture problems, chipboard structures can quickly weaken and fall apart. So it’s best if your product is already sensitive.

4. Rigid Boxes

Next, this packaging is typically used for luxury items or high-end electronics. Think Apple, Tiffany, Rolex, etc.

It is similar to corrugated but stronger because it is made of highly condensed paperboard. It is four times thicker than a standard folding carton!

This is one of the most expensive corrugated options, but for good reason. It signals to the customer that your product deserves the upgrade in cost.

A big downside of this packaging is its difficulty in efficiency. Apple has done a great job, but not everyone can maximize the air-reduction inside the box and are therefore shipping empty space.

5. Poly Bags

A Poly Bag (aka Pouch, Plastic Bag) is manufactured out of compact, thin plastic film. It is one of the most popular packaging styles and can hold a wide variety of items.

Think food products, chemicals, fertilizers, magazines, flowers, etc.

These are very durable, lightweight, flexible, and sometimes reusable. They are a very simple structure to make, which makes them excellent at branded customization - while remaining a cost-effective option.

One thing to note is that not all Poly Bags are created equal. Depending on the construction you choose, poly bags can be recyclable.

The positives are apparent: security features, hanging holes, handles, and more. This helps your product stand out, feel secure, and catch customers' attention.

6. Shrink Wrap

Now, Shrink Wrap can be either primary or secondary packaging, and sometimes even both. You can shrink wrap your products and a pallet of shipping boxes that are tightly packed together during shipping.

This protects your packaging against puncture and abrasion and increases its impact resistance. Individually wrapping your products in Shrink Wrap can also give them a greater visual appeal to customers.

It is one of the most commonly used packaging options out there and one you should consider.

7. Shock Mount Packaging

If you have fragile items, this is one of the safest packaging options.

This packaging's structure incorporates shock absorption, shielding the contents from shocks or vibration. Some options even protect against moisture, humidity, and dust.

This heavy-duty packaging is one of the best options for fragile electronic goods or an unstable chemical.

What’s important is finding the balance of safety, protection, and cost-efficiency with your packaging.

8. Vacuum Packaging

Finally, Vacuum Packaging is an excellent choice for products that need to be safely sealed, such as retail products and perishable food items.

Vacuum packaging is a great option for goods that need to be sealed, which makes it a preferred choice for perishable foods. Food that arrives with vacuum wrapping can remain fresh longer in the freezer than food packaged in other container forms.

This method is also used for medical materials and other health-related products. Vacuuming and sealing the products eliminates all oxygen, preventing bacteria from developing.

Can I Improve My Packaging?

Your packaging is some of the most valuable real estate for you. It creates a mini-billboard for you at retail, and when you stack several products in a display, you create a full-size billboard effect at retail.

Think about your target audience and even conduct focus group testing. Watch how they interact with your packaging. What are the biggest issues?

Do not wait until the last minute to consider these improvements. You should constantly return to your key questions and goals to ensure you’re going in the right direction.

Bennett Creates Custom Product Packaging

Bennett is a premier packaging and retail displays manufacturing company striving to protect and promote our clients' products with customized corrugated solutions. When you work with us, you’re part of the family. We will partner with you every step of the way.

With our fully integrated design-to-delivery process, we can be the single supplier source. We are an award-winning manufacturer of virtually anything corrugate. We offer everything from plain brown shipping boxes to sophisticated, high-graphic printed point-of-purchase displays and everything in between.

Frequently Asked Questions

What’s the difference between “Solid Board” and “Corrugated Packaging”?

There are 2 main types of product packaging. Solid board (also referred to as carton board) is a solid material used to create boxes such as those used by Apple (for its iPhones/iPads, etc.). Corrugated packaging is made from cardboard). Both are suitable for retail applications.

What packaging is best for my product?

The style of box chosen for your product depends on a number of factors. This includes your product's size, shape, weight, and fragility - and even your target market. At Bennett, we can offer the full spectrum of box styles that will take your brand from plain to premium.

What Printing Styles do you offer?

We can produce Litho and Flexo and specialize in Digital printing. We were one of the first manufacturers to invest in Digital Printing, which has put us ahead of the curve. Typically, customers think digital printing is only useful for small runs, but digital printing allows you to create printing variations and multiple runs of different targeted designs—using some of the latest innovations in marketing!