The Complete Guide To PDQ Trays + Counter Displays

We see this a lot at retail and club stores: simple, non-custom PDQ Trays that get the job done. How can you expect to hit your sales target if you don't invest in your presentation at the store?

You have a great product, a beautiful package, but you left out one thing - your display! A PDQ Tray is a great way to grab your customer's attention on the store floor. It's an easy thing for most brands to overlook, but this is exactly the issue we aim to solve.

Though customers are taking fewer trips to retail every year, each trip has tripled in value - meaning you must catch their attention.

PDQ Trays vary in size and shape depending on retailer requirements but are great for keeping products organized and presentable and driving brand awareness. These are a more economical option when compared to Sidekicks, Floorstands, and other larger displays, but they are just as effective at driving sales. If you want to see more benefits, read about them here - Benefits Of Using PDQ Trays.

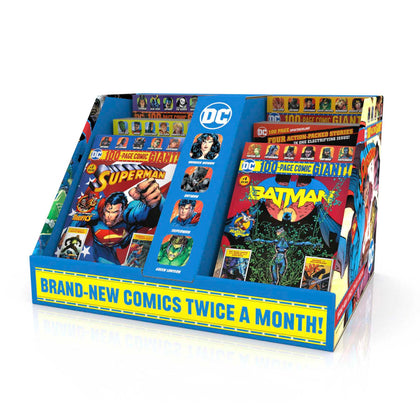

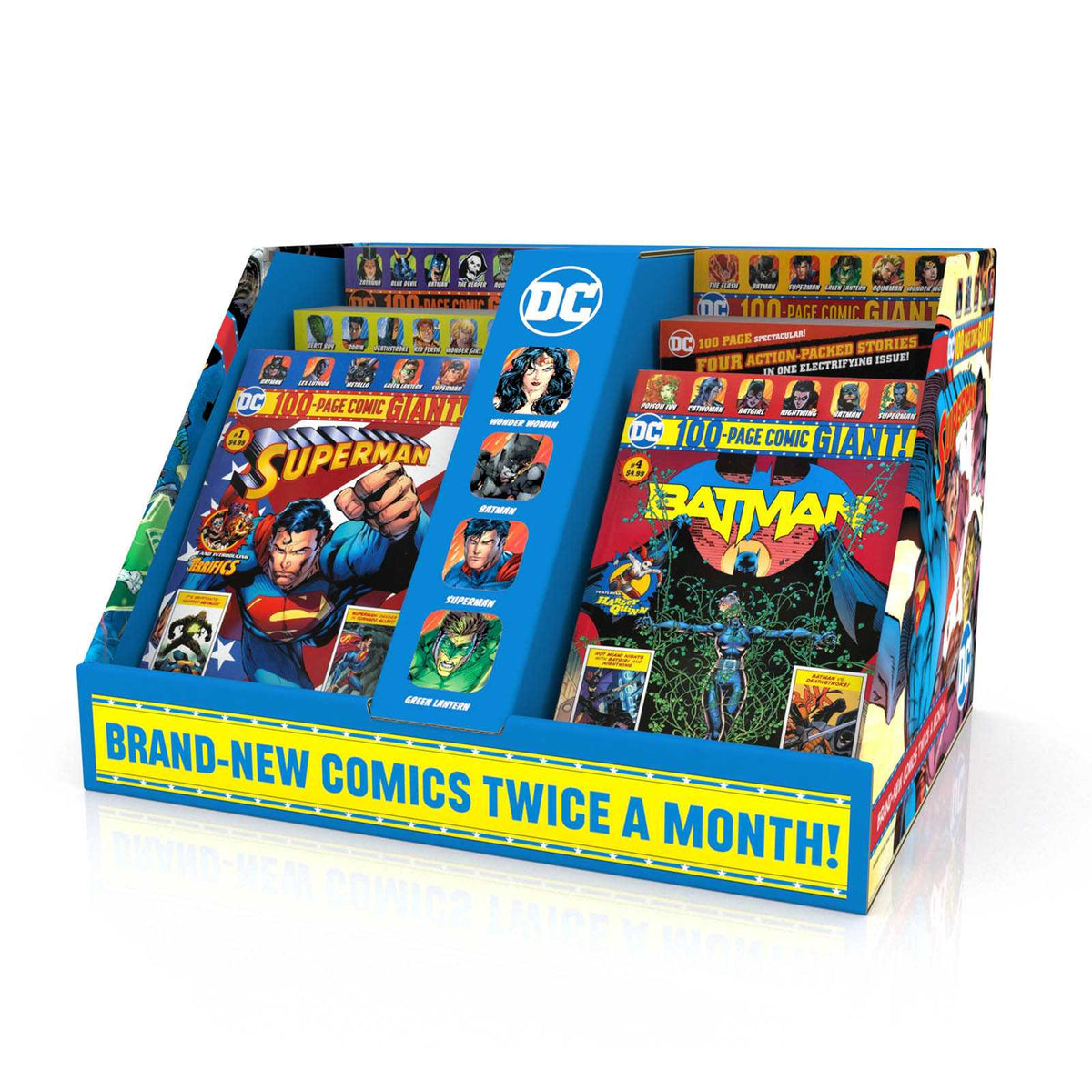

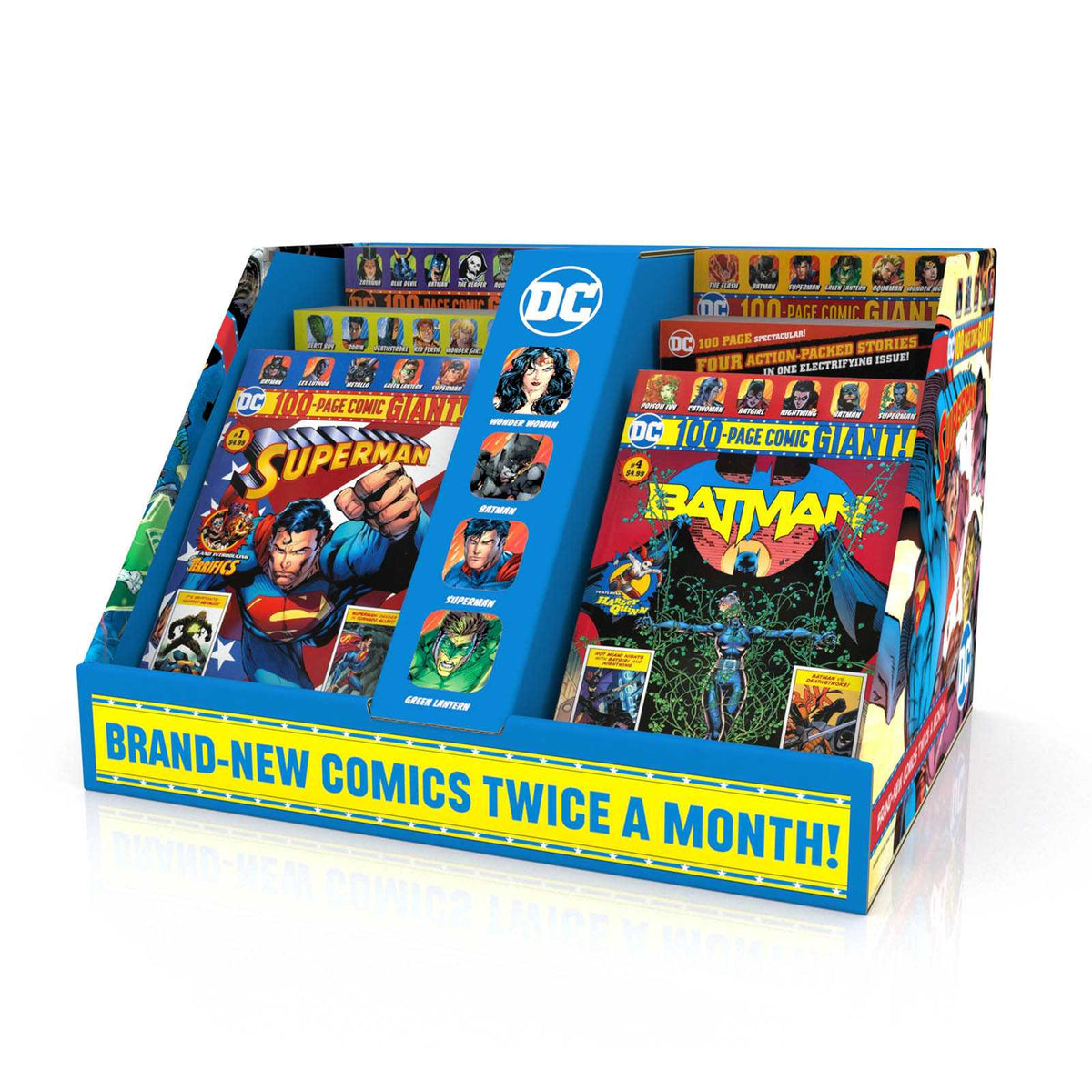

We help upgrade brands from plain to premium with our custom digitally printed PDQ Trays. A Counter Display is a point-of-sale retail display - or POS Display - used to promote and sell products.

Table Of Contents

What Is A PDQ Tray?

A PDQ Tray (Pretty Darn Quick) is a small display usually shipped with products, and can be placed on another POP Display or near the cash register. PDQ Trays are typically used in supermarkets, convenience stores, and even hardware and club stores to increase product exposure and encourage impulse purchases.

Aspects of a PDQ Tray

- Can vary in size or shape depending on the retailer's requirements

- Keep products organized and presented well

- Right at the register - aiming for impulse purchases

- Very economical compared to other displays

- Variety of structural designs to maximize presentation and stock holding

- Easily assembled and merchandised by shop staff

- Low cost allows for use as part of seasonal promotions or product launches

- We are pre-approved with most retailer and club store requirements

Step 1: Determine Your Needs

- What type of product do you have?

- Are there new innovations you can implement?

- How many units do I need?

- How can this be an extension of my brand?

- Which retailers/club stores are you selling at?

Step 2: Designing PDQ Trays

Designing can be a fun process. Whether you’re tackling it, or working with our Creative Services team, you need to consider key things about your retail display, and your customer.

- Who is your target demographic?

- How tall are they?

- Are you selling multiple items?

- Is this a promotional item?

- Can you create alternate designs for seasonal/regional messaging?

Step 3: Choose A Printing Style

Choosing a printing option is more than simply looking at cost factors. The technology has been changing over the years, and while some older methods are still proven and effective, newer methods have introduced completely new ways to attack the marketplace.

Here are three printing options to consider:

Lithography Printing

When it comes to commercial printing needs, lithographic printing is the most used solution. And it’s great if you are creating a single design to print over and over without much customization.

One of the primary concerns involves the initial costs associated with the printing plate and the lead time required for the project. Choosing lithography (Litho) means you commit to both a waiting period and allocating a portion of your budget upfront before receiving your first box.

If you are looking for a high-volume production run of a single design, this is the way to go.

High-Speed Digital Printing

Bennett's digital presses are game-changing for the custom retail display industry. While other companies might tell you that Digital isn’t competitive when running large orders, what they aren’t telling you is with Digital, you can run a variety of designs and be extremely cost-effective.

No need to pay for, or wait for, new printing plates to be made!

Digital has been growing in the industry, but only a few brands have actually started to take advantage of this huge opportunity.

Imagine creating regional messaging, designs for different stores, seasonal or product variation sizes - all without additional costs.

We were the first to invest in a high-speed, single-pass, direct-to-corrugate, 6-color digital press of its kind in North America. If you want to learn more, check out our page on Digital.

Related: Digital Printing Can Help Make Your POP Display More Sustainable

Flexography Printing

Flexographic printing will bring your cost of printing down, and tooling costs are typically lower. It has a fast turnaround time that can use both water and oil-based inks. But, compared to Lithography and Digital, Flexography has a noticeably lower printing quality.

It cannot create photo-quality images, and smooth colors or gradients will have visible banding.

The colors aren’t as vibrant or crisp as the other two options, but this format of printing is inexpensive. It also doesn’t require much attention to detail and can be produced at very high speed.

High Speed Digital Printing

Digital Printing has opened up completely new avenues for brands to create a PDQ Tray. The biggest advantage of a digitally printed PDQ Tray is to use alternate print designs.

By using this approach, you can create seasonal messaging, regionally targeted messaging, or simply create a new look when you need to replace the display.

Each new print won’t incur additional costs thanks to Digital - because you don’t need printing plates. There’s no slowdown to get you to market.

There are no minimum quantity orders, which is great for the initial proofs - but even better if you run 4-versions of a display rather than a one-size-fits-all approach.

Digital opens up a whole new world of possibilities - and we were among the first to invest in this game-changing technology. That has put us ahead of the learning curve in the industry.

Check out these Digital Printing Tips For PDQ Trays

Designing PDQ Trays With Digital

Here are some design tips to create an effective PDQ Tray from the ground up:

Strategic Location

You’re right at the register! Talk about a strategic location. This display is all about putting the right products on display for the right store.

Information Architecture

Messaging needs to be clear and motivated. What should your customers know as they pass by the display? What can they see from across the store? Keep it concise and focused! Only the important benefits should be included.

Product Showcase For PDQ Trays

You want a clean and organized presentation of your products to catch the customer’s attention. They are ideal for showcasing a new product or even a promotional offer to drive purchases.

Restocking

So many businesses simply fill a quota of product in their display. They forget a customer has to interact with the display and take the product out. That said, you want the display to be easy to restock for retailers to keep selling your items.

Color Science

Each color speaks to the customer on a different emotional level. That's something all designers know. Why not use that on the store floor? Here's an actual opportunity to put that knowledge into practice and create something that matches your brand in a powerful way.

Match Your Brand Colors

Most manufacturers claim they will match your brand colors accurately, but they're not actually equipped to do that. We have some of the best printing capabilities in North America, and promise we can actually match with 100% accuracy.

Refreshing Your Look

Consider how often you will need to replace your display over the year. Each time you do is a chance to attract more customers - so why not harness the power of Digital Printing and create a fresh look for your display at a fraction of the cost - and without slowing your speed to market?

Turnkey Solutions

A great display is key, but don’t forget about things like warehousing and fulfillment. You need a plan to get your display made, packed, and sent out to retailers.

That’s why we offer turnkey solutions including Contract Packaging, Shipping Boxes, and Packaging Supplies. The more downtime you have with a display, the less money you make. More on that later.

Read 5 Design Tips for PDQ Trays

Retailer Compliance

When you are creating a new display, or updating an existing design, it’s important you are confident that your new partner understands all the current retailer and club store compliance guidelines.

If you design a PDQ Tray for retailers that won’t be approved, you will have to start all over.

You need a partner that not only designs and manufactures PDQ Trays, but also understands the entire production process to get you to the storefront as fast as possible.

Step 4: Establish Your Budget

A successful PDQ Tray program depends on your understanding of the entire budget and economics of the entire process. Setting a budget for your display is an important step before beginning the design process.

Without a budget or even a range, the process will become inefficient and aimless.

When creating your budget, consider the price of your product, your profit margin, anticipated sales, and the length of time you expect your display to be in place.

The higher the sales price of your product, the more you should consider investing in your display.

How Quantity Affects Cost

After material costs, the best way to manage per-unit display costs is volume. Each display design will require tooling, set-up time, and upfront costs.

The longer the manufacturer can run, the more units you can use to spread those costs out.

But thanks to Digital Printing we can create multiple graphic designs for your display without increasing costs for those changes.

Using a single design shape, but unique seasonal designs, you can look brand new at retail while keeping your costs relatively the same.

Example:

If you order 2000 Units at once, You would need to pay all upfront tooling costs, wait for the project to be prepped, and purchase all the materials upfront. Then consider the entire supply chain, including storage, of your 2000 Displays.

If you order 5 runs of 400 Units over 3 Months, You would need to pay all upfront tooling costs and wait for the project to be prepped, but only purchase the initial materials upfront. Then you can actually redesign the graphics of the following 4 orders of 400 Displays.

Although both orders are purchasing 2000 units, the second order has more design flexibility and lower upfront costs to get started in the market. Because of Digital Printing, the difference between short runs and long runs is no longer much of a factor in cost.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Illum neque eaque, autem sit soluta, voluptatum libero magnam tempore ullam at harum vel, ad reprehenderit, nemo veniam quas in voluptas hic. Lorem ipsum dolor, sit amet consectetur adipisicing elit. Natus id officia omnis suscipit aut architecto repellat a quia eaque reiciendis blanditiis perferendis hic, nihil, mollitia. Iste velit aperiam, numquam dolorem.

Step 5: Creating a Dieline

Now that you have your design in place, it’s time to transfer it to the structure template, a.k.a, the dieline.

There are a few dieline and artwork preparation and requirements that need to be noted by your designated designer, even if your artwork is done and ready to go.

If you do not have a designer, then your packaging company will take care of this for you.

Dielines

A dieline is typically created on a computer with a designing tool such as Adobe Illustrator, Artioscad, or Adobe InDesign. Measurements need to be precise to save time and money.

Step 6: Preparing The Artwork

Working with your packaging partner, you will deliver high-resolution quality artwork for printing. It’s best to speak directly to the company you are working with to determine the exact specifications for their CMYK printing.

At Bennett, we offer access to our award-winning Creative Services to help you design, prep, and deliver all your artwork to our manufacturing teams - and ensure your project details are correct every step of the way.

Need more clarification on preparing your artwork? Reach out to Bennett; we can help with any of your design needs!

Step 7: Creating A Prototype

You should always request a prototype display to confirm the structure and printing for final production, especially if you have a very large order.

Once the prototype is created, it can be delivered to you in person or via mail carrier.

We have an array of equipment in our Creative Services Department that will match the exact quality of our High-Speed Digital Printers to allow you to get prototypes quickly - and move your project along to production.

Step 8: Production + Shipping

Once you finalize everything, your retail display is ready to go into full production. You can sit back, relax, and wait for the arrival of your display!

Receiving your shipment all depends on your requested timeline, the size of the display, the method of delivery, etc.

It is different depending on your situation, but your account manager will keep you up-to-date with the production and shipping process, ensuring that you are always on track.

Learn more about our Contract Packaging

Key Questions:

- Will your Display be shipped fully assembled or KDF?

- What is the weight of your Display with your Shipping Box and Supplies?

- Where will you store your Display?

- What is the cost for Packaging Supplies?

- Fulfillment costs, if any?

- How will you account for returns?

Pro Tip: If you need to order on a consistent basis, speak to a packaging specialist to map out your inventory expectations and schedule. This will make it easier to maintain a healthy inventory flow and allow the manufacturer to know exactly when you need it.

Shipping PDQ Trays Fully Kitted

Over the years, we have been delivering fully kitted displays for customers across the United States without issue. Choosing this option is a great way to reduce costs.

The fewer hands your Displays and products have to touch, the lower your costs.

Shipping PDQ Trays Knocked Down Flat

Shipping KDF is a great option if you want to assemble in your own facility and prefer the safer and cheaper shipping method. Thanks to the stacking efficiency, it’s easy to see why this is a great way to cut down on costs for some companies.

But, you will need to create and include a set of clear assembly instructions along with a parts list and any tools required for assembly.

Selecting The Right Box And Shipping Supplies

To ensure your Display arrives safely, it’s important to pick the right type of corrugated material and packaging supplies for the job.

You’ll want to talk to your manufacturer or 3PL provider to consider the best shipping box and packaging material to use.

Learn more about our Packaging Supplies

ISTA Testing For PDQ Trays

International Safe Transit Association (ISTA) testing helps brands to create packaging that will protect against shock, vibration, compression and any other atmospheric hazards in the distribution environment.

This allows you to eliminate the need for multiple trial shipments and get your products to market faster while also ensuring their survival.

It can also help you negotiate lower freight and cargo insurance rates - due to the confirmed lower risk of shipment damage.

We conduct a range of shipping tests (vibration, drop test, etc.) so that you are certified and ready to go.

We partner with you through the entire process and make sure there aren’t any surprises - and if there are, we are ready to solve them.

You’ll want to make sure your provider can safely deliver your Displays as a 3PL.

Step 9: Following up

One of the most important things you must do is stay on top of maintenance.

Don’t neglect your display upkeep. Even the best displays will lose their appeal if they look dusty or worn down. Remember, your display represents your brand and your product - if you invest in a great display, you should make sure it stays presentable.

Displays should be checked regularly, even throughout the day. That way you can be confident they never appear “shopworn”.

If you invest in a great display, you should make sure it stays presentable. These displays can really help you increase sales!

Retail Store Audits

Brands and product companies should regularly perform retail audits to ensure stores’ merchandising is compliant with agreed-upon standards.

The retail store audit process checks merchandising execution, including:

- Correct product placement, including location in the store.

- Product expiration dates.

- Item counts on shelves and in back-room inventory.

- Count of facing items per SKU.

- Sufficient and accurate signage.

- Usage of floor and shelving space.

A number of people can perform audits for you. Retail staff, brands, or even third parties can complete the task, but be sure to give them a checklist and get photos.

Audits help retailers and brands hold each other accountable. After all the agreements are in place for floor space allotment, signage, and other elements, retail store audits verify the deal, and everyone is happy.

Thanks to the latest innovations, you can use software that includes inventory management and automated audit-based reordering - all great tools that can further the benefits of audits and help keep your supply chain moving.

Bennett Creates Custom PDQ Trays

Bennett is a premier packaging and retail displays manufacturing company striving to protect and promote our clients' products with customized corrugated solutions. When you work with us, you’re part of the family. We will partner with you every step of the way.

With our fully integrated design-to-delivery process, we can be the single supplier source. We are an award-winning manufacturer of virtually anything corrugate. We offer everything from plain brown shipping boxes to sophisticated, high-graphic printed point-of-purchase displays and everything in between.

Frequently Asked Questions

What are PDQ Trays or Counter Displays?

A PDQ Tray or Counter Display is typically placed by the register, and they are used to hold multiple pieces of merchandise for quick stocking and restocking of the sales floor. They are great for keeping products organized, presenting well, and driving brand awareness at retail. They vary in size and shape depending on the retailer, but can be made completely custom to fit any purpose.

Are you retailer and club store compliant?

Of course! We have great relationships with all major retailers and club stores, and are up to date on the latest specifications and guidelines for complete compliance. If you want to go to Walmart, Target, CVS, Walgreens, Costco, Sam’s Club, Bjs, or any other store - we can get you there.

Where can I order retail displays?

Bennett offers a wide variety of retail displays. No matter what kind of product you have, or display you need, we can make it. Just Contact Us and we’ll get back to you ASAP!

What Printing Styles do you offer?

We are able to produce Litho, Flexo, and specialize in Digital. We were one of the first manufacturers to invest in Digital Printing, and that’s put us ahead of the curve. Typically customers think Digital is only useful for small runs, but Digital allows you to create printing variations and create multiple runs of different targeted designs - using some of the latest innovations in marketing!