Flexography print, commonly referred to as flexo, is a form of relief printing that utilizes a flexible relief plate. This printing method is ideal for high-volume jobs and offers superior quality results at faster speeds than other traditional forms of printing. The plates used in flexo are made from rubber or photopolymer which makes them resistant to wear and tear. This type of printing is often used for packaging purposes, labels, newspapers, magazines, books, and other materials that require a higher level of detail.

Flexo offers several advantages over traditional methods such as offset printing because it requires less setup time and can be completed in just one pass through the press. Additionally, flexography prints are much more cost-effective when compared to other forms of relief printing due to its quick turnaround times and reduced waste. Flexographic printers also feature a wide range of color options which allows for greater flexibility in terms of design possibilities.

Table Of Contents

Definition Of Flexographic Print

Flexographic printing is a widely used method of printing on custom packaging and pop displays. It is one of the most versatile form of printing, as it can be used to print on a large variety of substrates such as paper, plastic, corrugated board, foil, and non-woven fabric. The process begins by creating a relief image in the form of etched rubber or polymer plates, which are then mounted to a cylinder. Ink is applied to the surface and then transferred onto the substrate using pressure. This process creates sharp images and vibrant colors that are ideal for use in retail settings.

What Is Flexography Print

Flexographic printing is best suited for surface printing on a variety of substrates ranging from paper to film, metal foils and plastic. It is ideal for printing labels and other materials that need to be produced quickly and cost-effectively. This type of printing also offers superior quality when compared to other forms of relief printing while still being able to produce large volumes of material at high speeds.

Why Use Flexography Print

Flexography printing is ideal for any job that requires a large volume of prints in a short period of time. It is especially well-suited for packaging labels, tags, newspapers, magazines, books, and other materials that require high levels of detail and accuracy. The plates used in flexo printing are made from rubber or photopolymer which makes them resistant to wear and tear and helps ensure the quality of the printed product.

High Volume Order With One Design

Additionally, flexographic printing offers superior quality results at faster speeds when compared to traditional offset printing methods due to its single pass through the press and reduced setup time.

Cost-Effective For Large Orders Compared To Litho

This type of printing is also cost-effective as it produces less waste and allows for quicker turnaround times. This makes flexography an ideal choice for large orders compared to traditional lithography. The wide range of color options available also allows for greater flexibility in terms of design possibilities.

Long Term Repeat Orders

Flexography is also an excellent choice for long-term repeat orders due to its ability to produce consistently high quality results and its cost-effectiveness. The plates used in flexo printing are highly resistant to wear and tear which makes them ideal for producing multiple prints over a long period of time.

When Not To Use Flexography Print

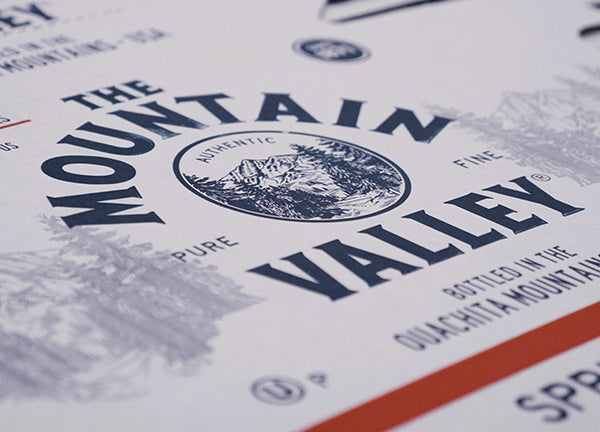

Flexography print is not suitable for high-graphic artwork or photographs with intricate details due to its limited color range and the difficulty in achieving fine detail. Additionally, flexo printing requires the use of plates, which can be costly when making multiple prints, making it an unsuitable option for low volume orders.

High-Graphic Artwork Or Photographs

If you have detailed artwork, Flexo might not be a great fit for your project. For artwork with intricate details and high-graphics, offset printing is usually a better option. However, Flexo can be used for labeling and similar applications that require a high level of accuracy.

No Budget For Tooling Costs

Everyone is on a budget, and Printing Plates require one-time upfront costs. Because of this, Flexo might not be a great fit for low volume orders. Offset printing or digital printing are usually better options here due to the lower upfront costs and shorter lead times.

You Need More Than 7 Colors

While most Flexographic Printers are capable of 1-3 Colors, we have a 7 Color Printer with UV available to customers. Allowing for a streamlined single pass to speed up production, and keep costs low.

Do More With Bennett

Flexography printing is an increasingly popular choice among businesses today due to its ability to produce large volumes of material at high speeds with superior quality results. It offers a cost-effective solution for long-term repeat orders and can be used on a variety of substrates ranging from paper to film, metal foils and plastic.

Additionally, the wide range of color options available makes it ideal for packaging labels, tags, newspapers, magazines, books and other materials that require detailed accuracy in their prints. At Bennett we offer Flexo printing capabilities up to 7 colors with UV curing, and more!

Latest Posts